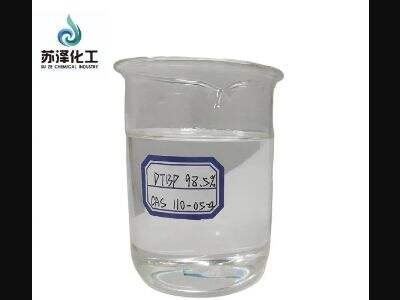

Have you ever heard of TBPB? If you haven't, that's totally fine! TIPB, or TBPB, is a hybrid chemical used extensively around the world to prepare robust elastomeric plastics in use today. Let’s dig into what TBPB is, how it works, and why TBPB is so significant when it comes to plastics.

What is TBPB?

TBPB = tert-butyl peroxybenzoate. This is a big name for a substance that plays a role in creating a special process. This turns small parts known as monomers, similar to bricks, into structures known as polymers. The distribution box polymers that make up plastics. Turned into polymers kind of process, is really important in giving plastics their unique properties, such as being flexible, strong or transparent.

Why Do We Use TBPB?

TBPB does its coolest magic at high temperatures. That means it could help trigger the process at the temperatures at which plastics are being produced, even if it’s scorching hot outside. Since TBPB has a role in structural fabrics and higher temperature operations, it will help enable plastics that can handle the extreme conditions. For instance, certain plastics require resistance to high heat or strong chemicals, something TBPB allows for.

How TBPB Is Transforming the Plastic Production Industry

Prior to TBPB, other types of chemical were used to initiate the plastic-making process. But those chemicals did have some issues. Some of them, for example, could work only at relatively low temperatures or with certain types of plastics. This made it super difficult for scientists to figure out how to create new5 types of plastics with various characteristics.

Thanks to TBPB, scientists now have many more choices! They can also produce countless kinds of plastics with exceptional qualities that did not exist before. This is Isobornyl Ester super important for things like planes, cars and electronics. 4. TBPB makes it happen, where strong and reliable materials are required in these industries.

The Good Things About TBPB

It is also one of the best methods suited for pairs of monomers for which TBPB works well. That means it could be used to make a wide variety of plastics, each with different properties. It can also be made to create lapJNIeJbXKJMyIcgyci066Fz plastics that are very flexible or ultra-tough plastics. Item #7: Another wonderful thing about TBPB, both for individual consumers and institutions is that it does not require refrigeration. That means it won’t decompose or change over time when it’s stored, so it can be easily stored for later use.

This is why TBPB makes a great building block for plastics

TBPB can be applied in many different slave environment. Either in liquid or solid form, and at varying temperatures, they can help start the plastic-making process at many different times. This flexibility allows scientists to have more control over the final properties of the plastics.

How it is useful: There are some interesting eligibility of TBPB and one of them is useful for use in the preparation of copolymers. Copolymers: A unique subset of plastics formed from two or more types of monomers. These copolymers can exhibit excellent features distinct from the individual monomers, including higher flexibility and advanced resistance to chemicals. As a result they are quite handy for a wide variety of use cases.

Why We Like Using TBPB

Overall, TBPB has a lot of advantages for plastics production. This thermoplastic exhibits features that make it useful, such as its ability to work at high temperatures, remain stable, and form various types of plastics.

TBPB is an essential ingredient in the process of producing Dibenzoyl Peroxide powerful useable plastics and is what Suze promotes. Many of our products, such as the TBPB, help fulfill these requirements in multiple industries, including electronics, automotive, and packaging.

Therefore, the next time you encounter a strong and flexible plastic, TBPB may very well have done some heavy lifting along the way! Isn’t it astonishing that one compound can be so impactful on the textile we use every day?